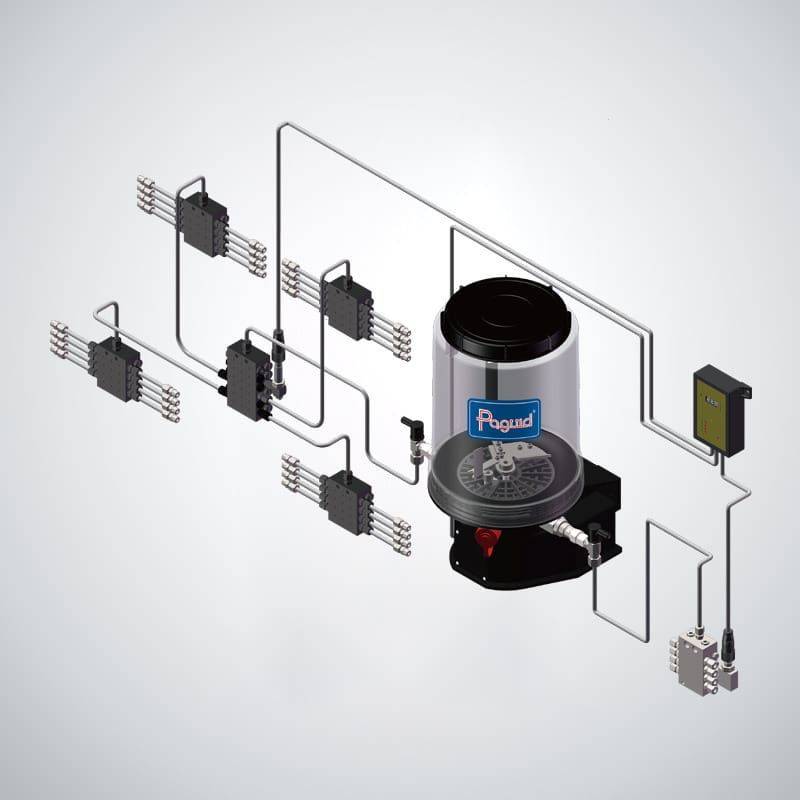

Paguld Automatic Lubrication Systems through Silveri Engineering, these products are widely used in wind power equipment, construction machinery, rail transportation, mining equipment, tunnel boring equipment, agricultural machinery, port machinery and other fields.

We are the suppliers of components for Single Line, Progressive, Multi-Line and Dual Line Systems. Leading technology, innovators and precision engineered products.

Contact Us +61 1300 766 413 | WhatsApp +61 458 047 075 | sales@silverieng.com

Lubrication Systems

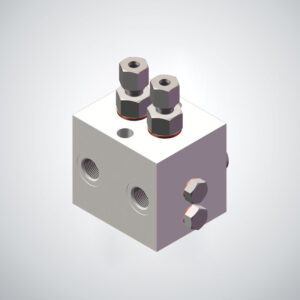

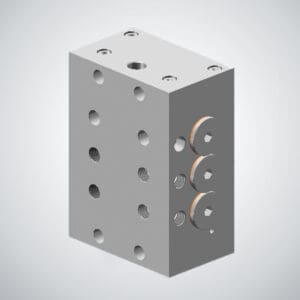

COMPONENTS

PG-HCH HYDRAULICALLY OPERATED GREASE PUMP

Loading...

Loading...

EPG ELECTRICALLY OPERATED GREASE PUMP

Loading...

Loading...

PARGULD - SILVERI MASTER LUBRICATION CATALOGU

Loading...

Loading...